A new temperature sensor for measuring the core temperature of feed pellets

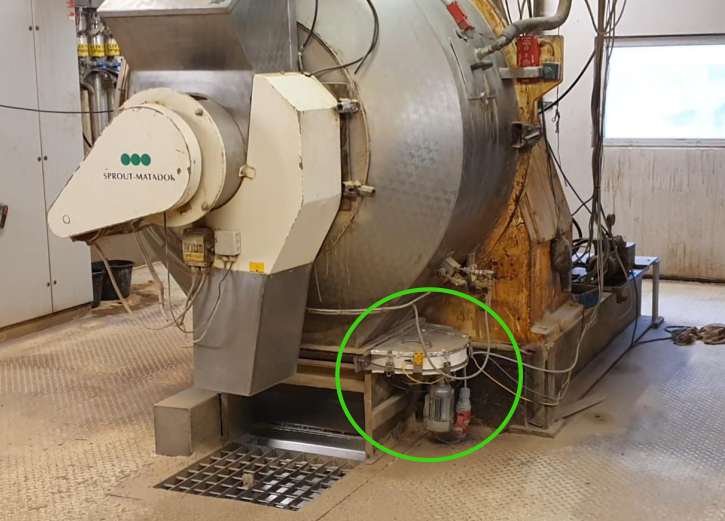

Today the compound feed industry is prevented from monitoring the core temperature of feed pellets efficiently during the pelletizing process. We offer a way of documenting heat treatment (in DK above 81 °C) and monitor the core temperature of feed pellets during that process.

Function

Our MPM-sensor is a multi-point temperature sensor, which is primarily developed for the feed industry. The device is an online temperature measurement for measuring the core temperature of feed pellets.

The sensor is used to directly regulate the pelletization process due to its fast reaction time.

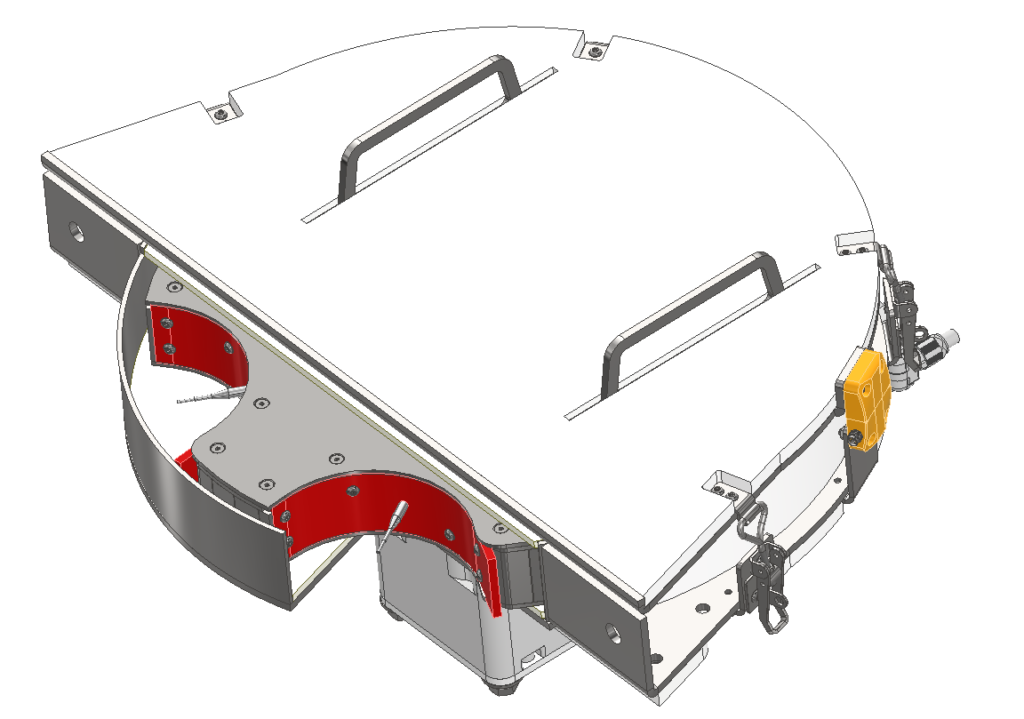

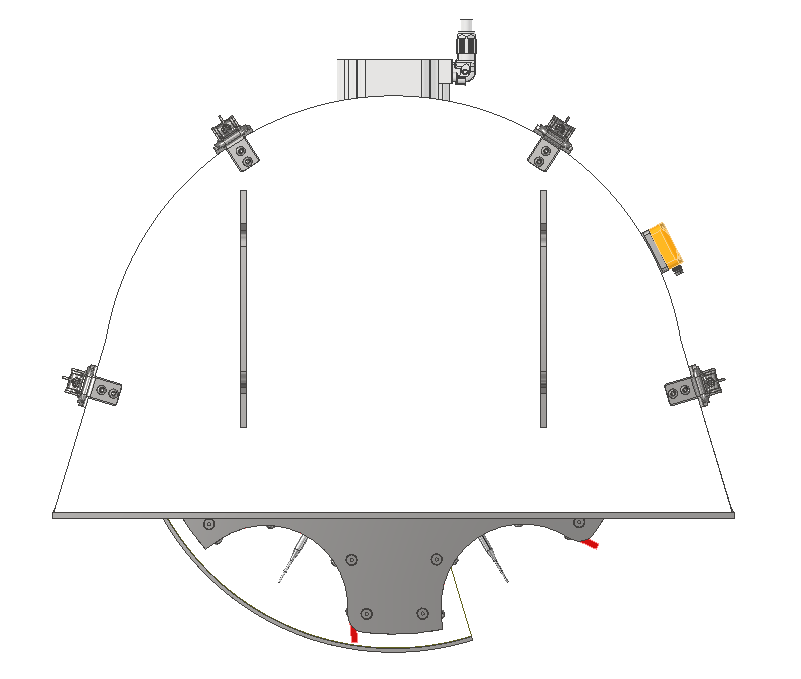

The temperature measurement is done by filling an airtight and insulated cell chamber with hot pellets directly from the pellet press. A temperature sensor is mounted in each cell chamber, which monitors the temperature of the pellets over a period of time. Over the course, the feed pellets are slowly compressed to create a more optimal temperature transfer between the feed pellets and the sensors, and in a way that does not damage the feed pellets.

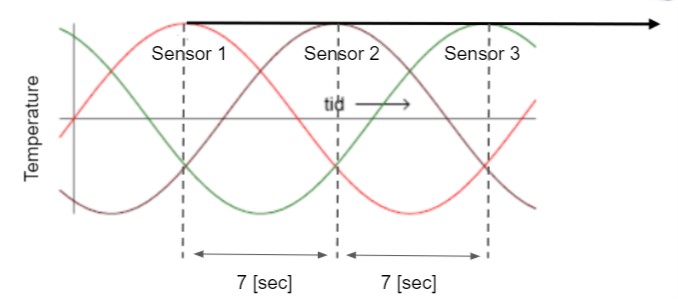

The sensor has a reaction time of 32 sec. That means the time that elapses from the sensor being covered with feed until there is a stable temperature measurement.

Each time a temperature sensor reaches an entire lap, a snapshot of the value of the sensor is taken. Which happens every 7 [sec].

All snapshots are collected into a signal (temperature), which is then sent as a 4 – 20 [mA] signal to the local SCADA system.

The MPM-sensor is patented in Denmark and internationally PCT- approved.

DK-patent nr. DK 180519 – PTC/EP2021/050997

Verification and control

In order to ensure that the method and accuracy of the measuring instrument is valid and accurate, Force Technology has performed an analysis and calibration of the MPM sensor.

What are the benefits of the device?

Due to its innovative design, the device is not capacity dependent – even a few hundred kilos per hour is enough to generate a temperature measurement.

In combination with the fast reaction time, it results in much less loss (material for re-pelleting) in both the start-up and shut-down phase, as we measure the heat of friction from the pelletizing process before the conditioner is up in temperature.

The measurement method is repeatable and uniform, and thus easy to integrate into a production, as it is an add-on solution for production facilities. In addition, there is a greater measurement certainty in relation to outcomes and defects on the sensors due to the amount of sensors.

Online and fast measurement

Inline system which gives a fast (32 sec) and constant picture of the core temperature doing the pelletizing process. (4 – 20 [mA] signal)

Easy installation

Plug and play ad-on system, with low maintenance.

Decrease energy consumption

Decreases energy consumption typical by (5%), which is equal to CO2 reduction of 30 tons per year.

Compliance through a verified measuring method

Verified measuring method by Force Technology that ensures a repeatable measurement method and compliance with current legislation.

Increases nutrition

Increases nutrition, by damaging less naturally occurring enzymes, vitamins and probiotics.

Less waste in the start-up process

Less waste in the start-up process, as you reaches the determined temperature faster.

Closed system

A closed system where there is no risk of contamination. Nothing gets in or out.